Remote Plant Operation & Maintenance

Need

-

Efficient

-

Cost-effective

-

Reduced downtime

-

Remote access to real-time data

-

Predictive maintenance capabilities

-

Collaboration

-

Empower teams

-

Monitor, maintain and optimize assets remotely

-

Maximize Asset performance

Challenges

-

Aging Infrastructure and Asset Obsolescence

-

Limited Asset Visibility and Tracking

-

Data Management and Integration

-

Limited Resources

-

Budget Constraints

-

Regulatory Compliance

-

Remote Maintenance Management

-

Unplanned Downtime

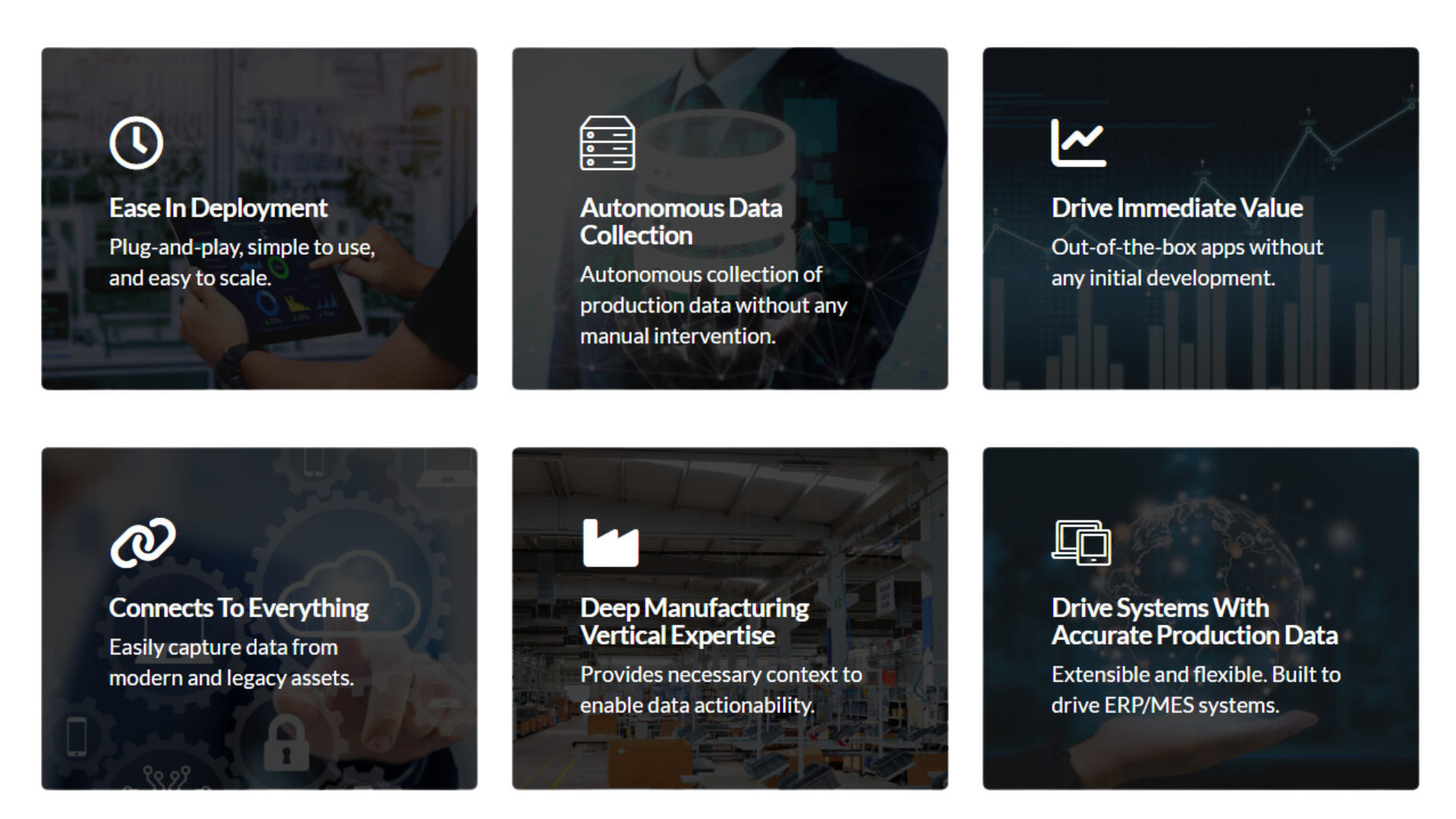

Solutions

Remote monitoring & alerts

Data Integrity and Analytics

Asset failure detection

IoT-Enabled Asset Management

Maintenance Planning & Spare Management

Safety & compliance

Work Order Management

SOP with knowledge base

Third party integration

Benefits

-

Early detection of equipment failures

-

Reduced maintenance costs

-

Improved production efficiency

-

Capture and transform non-instrumented data into contextualized information

-

Clear visibility into the state of the business

-

Enable well informed intelligent decisions

-

Consistent, compliant, best-practice execution of invasive tasks

-

Eliminate, minimize and mitigate risks to personnel, asset/s, and to the environment

-

Enforced use of validated procedures

-

Minimize risks associated with shutdown and restart

-

Verification of sustained regulatory compliance

-

Avoid the risk of fines or loss of operating license

-

Manage multi-location day-to-day maintenance life cycles

-

Maximize assets through mobile asset downtime tracking

-

Improve overall facility condition

Value Creation